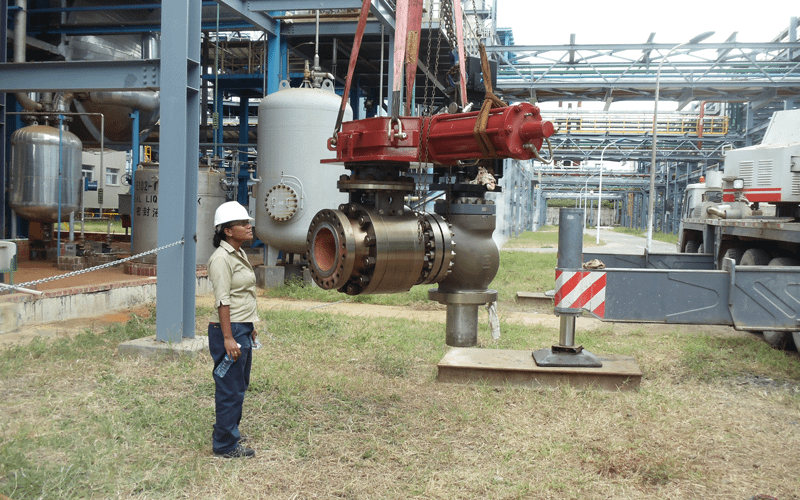

Pumps, Valves & Control Systems

Fimali is well versed at providing engineered solutions that supply, control and regulate most industrial systems. Supplying a comprehensive range of products ranging from, ‘individual components‘ right through to ‘complex multi-faceted projects‘ covering all elements involved in a multitude of operations:

- Pumps

- Mechanical

- Process

- Electrical

- Instrumentation

- Control

Fimali Products:

Operate safely, reliably & efficiently

Comply with the required industry standards

Are suitable for the application and meet the client’s requirements

Considers compatibility with existing equipment

In addition to non-tangible engineering solutions, such as technical assistance and installation/maintenance services etc. Please find detailed below, some of the many and varied products provided by Fimali Services:

- Hydrocarbon process pumps and systems

- Water supply/transfer pumps, pipework, valving and accessories

- Municipal and industrial Wastewater pumps, systems and equipment

- Industrial control and monitoring systems for high risk industrial & severe service applications

- Remote location water and wastewater systems and equipment

- Customised packaged pump stations & valve pits

- Customised water management equipment and systems for mining and hydrocarbon sector

- Bore hole pumping systems

- Mine drainage pumps, including specialised dewatering systems

- Transportable/skid mounted pumping stations and filtration systems

- Stand-alone filtration and treatment systems including refurbishment, modifications and conversions to existing stations

- Pontoon mounted pumps for water supply, dewatering, or desludging

- Dedicated fire pump stations for the municipality, general industry, mining, and oil/gas sectors

- Metering pump systems for the municipality, food & beverage industries

- Product flow control and metering systems

- High/low pressure/temperature valves, mechanical seals, and pipe flanges and fittings

- General supply of all OEM parts, add-ons, fittings and accessories